One objective:

top quality

Mechanical Casting

Type of casting:

Green Sand Casting.

Part weight range:

0.100 Kg. – 30 Kg.

Mould casting boxes:

Min 450 x 330 / H100 – 150 -200

Max 900 X 800 / H200 – 300

Moulding in machines is aimed at medium-long production runs to obtain optimum productivity.

We have two moulding lines (carousel) for which we have fully-automated, modern, green sand moulding equipment.

Manual Casting

Type of casting:

Green and chemical moulding.

Part weight range:

0.100 Kg. – 500 Kg.

This type of casting is aimed at prototypes, small production runs and at parts which, due to their dimensions, cannot be moulded in machines.

We have fully mechanised sand preparation installations and pneumatic and electrical manual equipment to perform the appropriate handling of the parts.

Shell Casting

Type of casting:

Permanent Metal or Shell Mould Casting.

Part weight range:

0.025 Kg. – 50 Kg.

Aimed at medium to long production runs, this mould casting provides excellent surface finish as well as improved mechanical characteristics by means of universal shell casting machines with electro-hydraulic and pneumatic drives.

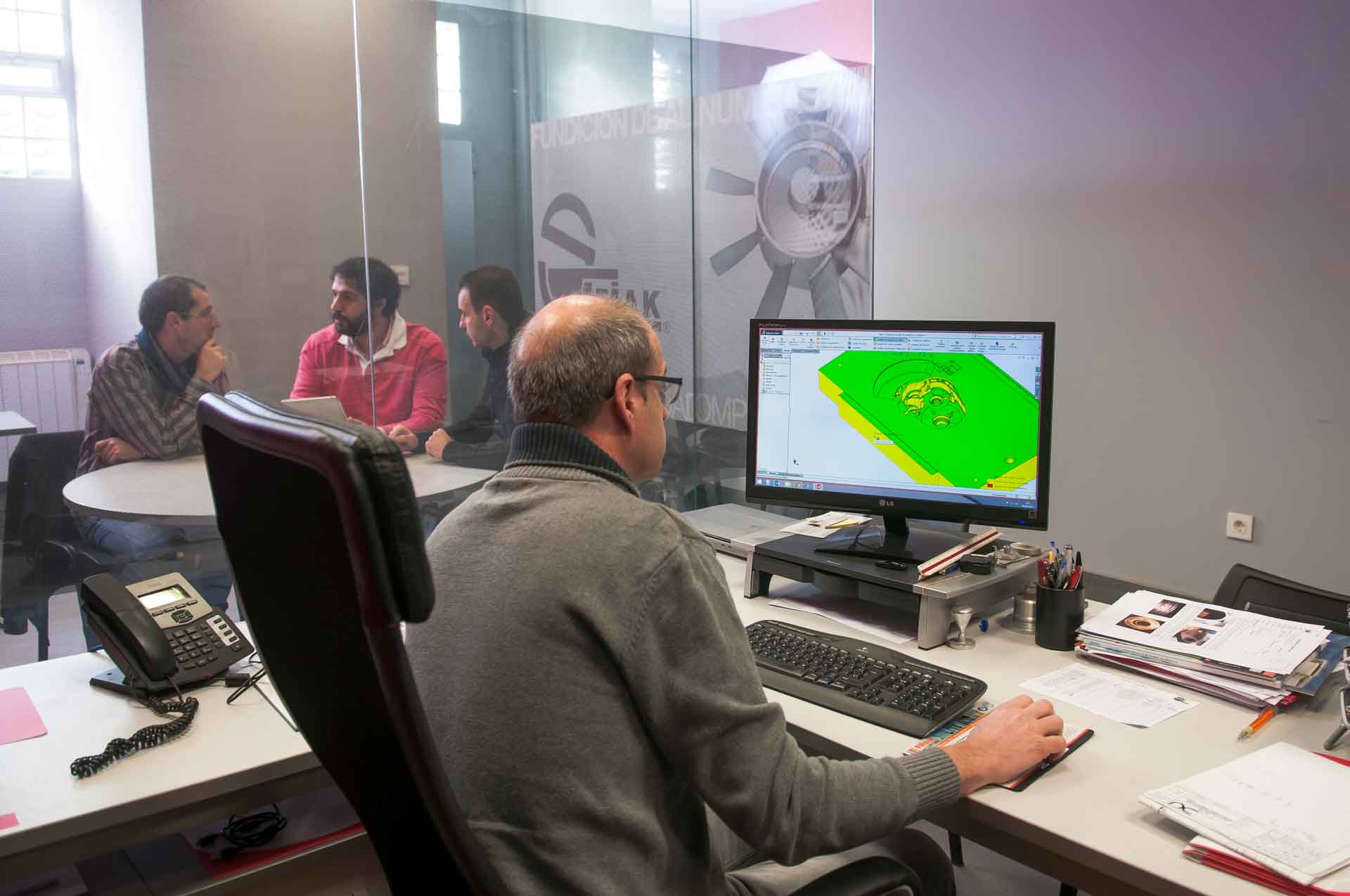

Technical Department

We offer the customer a professional team with wide experience in designing moulds, equipped with the most advanced graphic design programmes and in constant contact with various production lines.

This team provides solutions to the problems of those of our customers who do not have technicians specialised in the design of parts or patterns on their staff.

Machinery

In this section we have mixers, core making machines and other machinery for the manufacture of cores to supply the different moulding lines.

Melting

We have both electric and natural gas crucible melting furnaces controlled by electrical cabinets with the associated pyrometric meters and installations for the transfer and handling of the castings.

This section is in continuous contact with the technical staff who are in charge of carrying out the castings controls as well as supervision of the various treatments given to the molten metal.

Deburring

This section is where the processes of cutting, grinding, blasting, dimensional control of the products and dispatch take place.